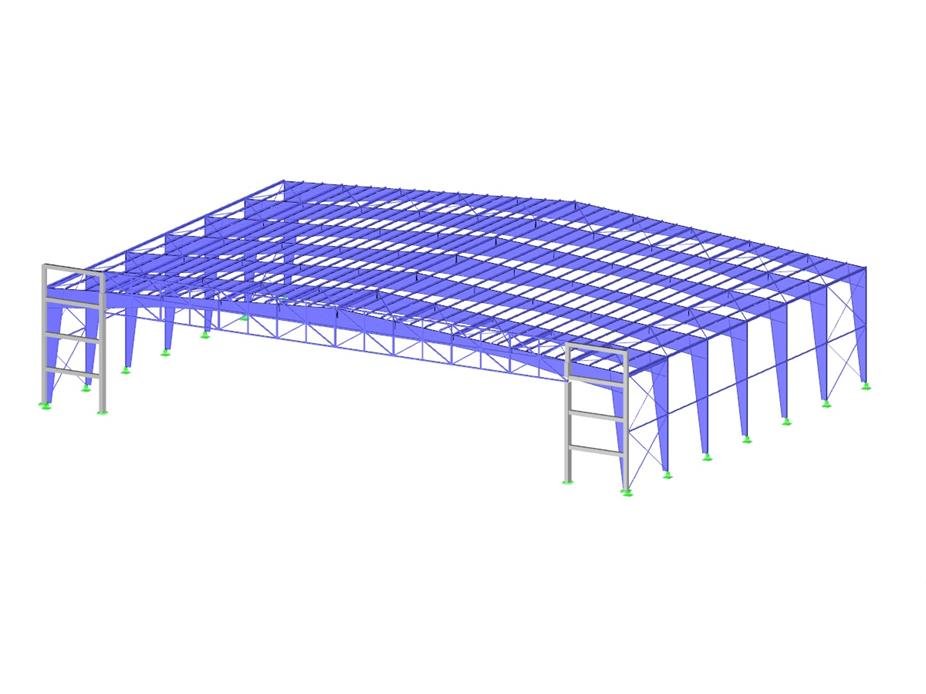

The construction timeline for a steel aircraft hangar can vary depending on factors such as the size and complexity of the project, site conditions, and permitting processes. Generally, prefabricated steel hangars can be erected more quickly than traditional construction methods, resulting in shorter overall project timelines.

Steel Aircraft Hangar construction contractors offer cost-effective solutions by leveraging prefabrication techniques, which reduce construction time and labor costs. Additionally, steel hangars require less maintenance and have a longer lifespan compared to other materials, resulting in lower long-term costs.

Steel Aircraft Hangar construction contractors typically use high-quality steel alloys for the primary structural framework, ensuring strength and durability. Additionally, they may incorporate galvanized steel for enhanced corrosion resistance, insulated sandwich panels for temperature control, and high-performance coatings for added protection against environmental factors.

+971 52 807 8039

+971 52 807 8039